level 3 hard body test|USG Sheetrock® Brand Abuse : manufacture dents by small hard objects. This is evaluated by dropping a round-tipped rod onto the gypsum panel. The depth of the indentation is measured after impact. Large liquid loads take an exceptionally long time to heat, which can cause sterilization cycles to abort. Therefore, the best way to sterilize liquids is to space them out in as many small containers as possible. Another way to prevent this common autoclave problem is to use an F0 cycle, which enables the autoclave to count the time that it . See more

{plog:ftitle_list}

$1,760.00

ASTM C1629 has four test methods to quantify a level of abuse/impact resistance. Each test has a classification level (1-3), with 3 being the best. XP Hi-Abuse and XP Hi-Impact Gypsum .

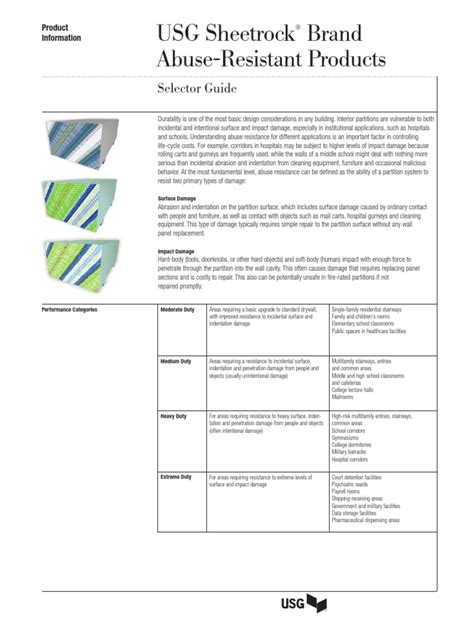

Hard-body (tools, doorknobs, or other hard objects) and soft-body (human) impact with enough force to penetrate through the partition into the wall cavity. This often causes damage that requires replacing panel sections and is costly to repair.ASTM C1629 has four test methods to quantify a level of abuse/impact resistance. Each test has a classification level (1-3), with 3 being the best. XP Hi-Abuse and XP Hi-Impact Gypsum Board were subjected to the four test methods: Surface abrasion, indentation, soft .USG testing demonstrates that when painted with one coat of primer and two coats of latex paint, the abrasion resistance increases to Level 3. Building design presents countless challenges, and USG can help you address key performance issues with our comprehensive portfolio of abuse- and impact-resistant solutions.

dents by small hard objects. This is evaluated by dropping a round-tipped rod onto the gypsum panel. The depth of the indentation is measured after impact. Body Armor Test Level 3 Spartan Armor Manufactured using Ultra High Molecular Weight Polyethylene (UHMWPE) Hybrid Fibers, these plates weigh in at a mere 3.5 pounds per 10×12 plate. We shot them up in our standalone Ceramic & UHMWPE Body Armor review. Can level III body armor stop rounds from an AR15 rifle? The answer depends on the round. Our Spartan™ Omega™ AR500 Steel Armor and Elaphros Lightweight level III plates have both been tested against M193 rounds (commonly referred to as .223 or 5.56). Level III: Resists rifle rounds, specifically 7.62mm FMJ lead core rifle ammunition. Level IV: The highest NIJ body armor level, designed to withstand armor-piercing rifle rounds.

Behind the scenes, the National Voluntary Laboratory Accreditation Program (NVLAP) will use NIJ Standard 0101.07 to accredit ballistics laboratories and, in spring 2024, the program will begin testing, evaluation, and certification of ballistic-resistant body armor to the updated standard. Level III hard body armor is designed to provide protection against the 7.62×51 M80 ball rounds, commonly used in hunting and battle rifles such as the FAL, M1A and AR-10. These plates can be made from steel, ceramic, or polyethylene.Level III: This hard body armor uses metal plates or other composite materials to withstand rifle rounds. The NIJ tests this armor to withstand 7.62mm FMJ lead core rifle ammunition. Level IV: Level IV is the most powerful body armor available.

Hard-body (tools, doorknobs, or other hard objects) and soft-body (human) impact with enough force to penetrate through the partition into the wall cavity. This often causes damage that requires replacing panel sections and is costly to repair.ASTM C1629 has four test methods to quantify a level of abuse/impact resistance. Each test has a classification level (1-3), with 3 being the best. XP Hi-Abuse and XP Hi-Impact Gypsum Board were subjected to the four test methods: Surface abrasion, indentation, soft .USG testing demonstrates that when painted with one coat of primer and two coats of latex paint, the abrasion resistance increases to Level 3. Building design presents countless challenges, and USG can help you address key performance issues with our comprehensive portfolio of abuse- and impact-resistant solutions.dents by small hard objects. This is evaluated by dropping a round-tipped rod onto the gypsum panel. The depth of the indentation is measured after impact.

Body Armor Test Level 3 Spartan Armor Manufactured using Ultra High Molecular Weight Polyethylene (UHMWPE) Hybrid Fibers, these plates weigh in at a mere 3.5 pounds per 10×12 plate. We shot them up in our standalone Ceramic & UHMWPE Body Armor review.

Can level III body armor stop rounds from an AR15 rifle? The answer depends on the round. Our Spartan™ Omega™ AR500 Steel Armor and Elaphros Lightweight level III plates have both been tested against M193 rounds (commonly referred to as .223 or 5.56). Level III: Resists rifle rounds, specifically 7.62mm FMJ lead core rifle ammunition. Level IV: The highest NIJ body armor level, designed to withstand armor-piercing rifle rounds. Behind the scenes, the National Voluntary Laboratory Accreditation Program (NVLAP) will use NIJ Standard 0101.07 to accredit ballistics laboratories and, in spring 2024, the program will begin testing, evaluation, and certification of ballistic-resistant body armor to the updated standard.

USG Sheetrock® Brand Abuse

Level III hard body armor is designed to provide protection against the 7.62×51 M80 ball rounds, commonly used in hunting and battle rifles such as the FAL, M1A and AR-10. These plates can be made from steel, ceramic, or polyethylene.

The Ins

lab pipette safety video through hand

lab pipette shaker

The Bottom Line About Specifying Abuse or Impact

Use liquid cycle (slow exhaust) when autoclaving liquids, to prevent contents from boiling over. Select fast exhaust cycle for glassware. Use fast exhaust and dry cycle for wrapped items. Take into account the size of the articles to be .

level 3 hard body test|USG Sheetrock® Brand Abuse